Vacuum Tray Dryer - VTD Leading Manufacturer, Supplier, and Exporter in India

Bipin Pharma Equipment is a recognized leader in the design, manufacturing, and export of high-quality machinery for pharmaceutical, chemical, food, and allied industries. As a prominent Vacuum Tray Dryer Manufacturer, Supplier, and Exporter, we deliver innovative solutions tailored to meet the diverse drying requirements of our clients.

Our product portfolio includes advanced filtration systems, granulation equipment, chemical reactors, and state-of-the-art drying systems like Vacuum Tray Dryers (VTD). With a commitment to precision engineering and quality, we ensure our products meet global standards and deliver reliable performance.

What is Vacuum Tray Dryer (VTD)

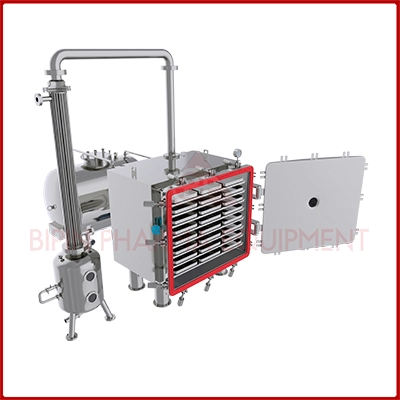

A Vacuum Tray Dryer (VTD) is a specialized drying solution designed to remove moisture from materials under reduced pressure. This low-pressure environment allows drying at significantly lower temperatures compared to conventional methods, making it ideal for heat-sensitive products.

Featuring a rectangular chamber with multiple trays, the VTD ensures uniform heat distribution and efficient moisture removal. The trays are heated indirectly using steam or hot water, while a vacuum pump creates the necessary pressure reduction to accelerate drying.

Key Features of Vacuum Tray Dryer

- Gentle Drying Process:

Operates at lower temperatures, protecting heat-sensitive materials from thermal degradation. - Uniform Drying:

Ensures consistent drying across all trays, preventing localized overheating or under-drying. - Controlled Atmosphere:

Can be used in an inert gas environment, protecting materials from oxidation or contamination. - Reduced Drying Time:

Vacuum conditions lower the boiling point of moisture, speeding up the drying process. - Versatile Handling:

Suitable for drying powders, granules, solids, and delicate heat-sensitive substances. - Energy Efficiency:

Consumes less energy compared to conventional drying methods due to its controlled conditions. - Easy Maintenance:

Features removable trays and smooth interior surfaces for hassle-free cleaning and maintenance. - Batch Processing:

Operates in batch mode, allowing precise control over drying parameters for each batch. - Customizable Options:

Available in various configurations, including tray sizes, construction materials, and automation features, to meet specific requirements.

Advantages of Vacuum Tray Dryer

- Preservation of Product Integrity: Gentle drying ensures sensitive materials retain their properties.

- Consistent Quality: Uniform heat distribution ensures even drying across all trays.

- Improved Efficiency: Reduced drying time and energy consumption enhance productivity.

- Flexibility: Suitable for a wide range of materials and industries.

- Ease of Use: User-friendly controls and simple maintenance streamline operations.

Applications of Vacuum Tray Dryer

- Pharmaceutical Industry: Gentle drying ensures sensitive materials retain their properties.

- Chemical Industry: Efficient drying of compounds, catalysts, polymers, and specialty chemicals.

- Food Processing Industry: Preserves and dries fruits, vegetables, spices, and other food products.

- Cosmetic Industry: Dries ingredients and formulations for creams, powders, and other cosmetic products.

- Agrochemical Industry: Used for drying pesticides, fertilizers, and other agricultural products.

- Material Processing: Ideal for drying sensitive materials used in advanced manufacturing and research applications.

Why Choose Bipin Pharma Equipment for Vacuum Tray Dryers?

- Proven Expertise: Decades of experience in designing and manufacturing reliable drying systems.

- Custom Solutions: Tailored designs to meet the unique requirements of various industries.

- Global Reach: Trusted supplier to clients in India and worldwide.

- Quality Assurance: Machines built to comply with GMP and international standards.

- Quality Assurance: Machines built to comply with GMP and international standards.

- Comprehensive Support: From installation to maintenance, we provide end-to-end assistance for seamless operations.

Bipin Pharma Equipment's Vacuum Tray Dryers are designed to deliver precision, efficiency, and reliability in drying applications across industries. Contact us today for more information or to request a customized solution for your drying needs.

Vacuum tray dryer different names industry wise and region wise

"Vacuum Tray Dryer" is known by different names worldwide, depending on theindustry, region, and specific applications. Some of the alternative names include:

General Synonyms :

- Vacuum Shelf Dryer

- Vacuum Oven

- Vacuum Chamber Dryer

- Low-Temperature Vacuum Dryer

- Vacuum Drying Oven

- Vacuum Cabinet Dryer

Industry-Specific Names :

Pharmaceutical & Chemical Industry:

- Pharmaceutical Vacuum Tray Dryer

- GMP Vacuum Tray Dryer

- Lab Vacuum Dryer

- Vacuum Freeze Dryer (For lyophilization applications)

Food & Agriculture Industry :

- Vacuum Food Dryer

- Vacuum Dehydrator

- Low-Temperature Food Dryer

- Vacuum Spice Dryer

Industrial & Engineering Applications:

- Vacuum Process Dryer

- Vacuum Heat Treatment Dryer

- Industrial Vacuum Dryer

Batch Vacuum Tray Dryer

The name "Vacuum Tray Dryer" varies across different countries based on local terminology, industry preferences, and language. Here are the specific names used in different countries :

North America (USA, Canada)

- Vacuum Tray Dryer (VTD) – Common industry term

- Vacuum Shelf Dryer – Used in pharmaceuticals and chemicals

- Vacuum Drying Oven – Common in laboratories and food processing

- Low-Temperature Vacuum Dryer – Used for sensitive materials

Europe (UK, Germany, France, Italy, Spain, Netherlands, etc.)

- Vakuumtablettrockner (Germany – "Vacuum Tablet Dryer")

- Séchoir à plateaux sous vide (France – "Vacuum Tray Dryer")

- Essiccatore a vassoio sottovuoto (Italy – "Vacuum Tray Dryer")

- Secador de bandejas al vacío (Spain – "Vacuum Tray Dryer")

- Vacuümplaatdroger (Netherlands – "Vacuum Plate Dryer")

China & East Asia (China, Japan, South Korea)

- 真空托盘干燥机 (Zhēnkōng tuōpán gānzào jī) – China (Literal translation of "Vacuum Tray Dryer")

- 真空干燥机 (Zhēnkōng gānzào jī) – China (General "Vacuum Dryer")

- 真空トレイ乾燥機 (Shinkū toreikan sōki) – Japan ("Vacuum Tray Dryer")

- 真空棚式乾燥機 (Shinkū tana-shiki kansōki) – Japan ("Vacuum Shelf Dryer")

- 진공 트레이 건조기 (Jingong teurei geonjogi) – South Korea ("Vacuum Tray Dryer")

India & South Asia (India, Pakistan, Bangladesh, Sri Lanka)

- Vacuum Tray Dryer (VTD) – Standard industry term

- GMP Vacuum Tray Dryer – Used in pharmaceutical & food industries

- Pharmaceutical Vacuum Dryer – Common in pharma companies

Middle East & Africa (UAE, Saudi Arabia, South Africa, Egypt, etc.)

- جفف صواني الفراغ (Mujafif ṣawānī al-farāgh) – Arabic ("Vacuum Tray Dryer")

- Vakuumblaasdroër – South Africa (Afrikaans, meaning "Vacuum Tray Dryer")

Russia & Eastern Europe (Russia, Poland, Czech Republic, etc.)

- Вакуумная сушильная камера (Vakuumnaya sushil'naya kamera) – Russia ("Vacuum Drying Chamber")

- Suszarka próżniowa półkowa – Poland ("Vacuum Shelf Dryer")

- Vakuová sušička zásobníků – Czech Republic ("Vacuum Tray Dryer")

Frequently Asked Questions (FAQs) about Vacuum Tray Dryer

A Vacuum Tray Dryer (VTD) removes moisture under vacuum at low temperatures, ideal for heat-sensitive materials in pharma, chemical, and food industries.

Benefits include uniform low-temp drying, energy efficiency, oxidation prevention, and suitability for sensitive products.

Used in pharmaceuticals, chemicals, food processing, cosmetics, and herbal industries.

It is ideal for drying powders, granules, crystals, and heat-sensitive materials including pharmaceuticals, chemicals, and food ingredients.

Regular maintenance includes checking vacuum seals, cleaning trays, inspecting heating systems, and ensuring the vacuum pump operates efficiently.

Yes, Bipin Pharma Equipments specializes in manufacturing customized Vacuum Tray Dryers tailored to specific industrial requirements and applications.

Vacuum Tray Dryers are highly energy-efficient due to low-temperature operation and reduced drying times, leading to lower operational costs.

Yes, many Vacuum Tray Dryers are designed to recover solvents during the drying process, making them ideal for pharmaceutical and chemical industries.