Industrial Vacuum Tray Dryer : Features, Advantages and Applications

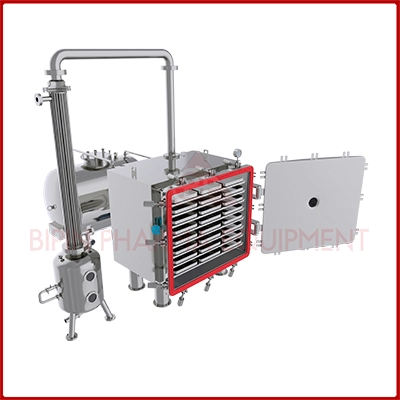

A Industrial Vacuum Tray Dryer (VTD) is a specialized machine engineered to efficiently dry materials that are sensitive to heat or prone to degrading under normal drying processes. This state-of-the-art dryer performs in vacuum conditions, which dramatically reduces liquids' boiling point and provides faster, consistent drying without any damage to the product.

Bipin Pharma, a top manufacturer, supplier, and exporter of Industrial vacuum tray dryers in India, provides innovative solutions that are specifically designed to suit the specific requirements of industries such as pharma, chemicals, food processing, and cosmetics. These dryers are designed to meet stringent cGMP requirements and ensure unparalleled efficiency, safety, and operational reliability.

Key Features of Industrial Vacuum Tray Dryer

- Vacuum Operation:

The vacuum environment enables drying at lower temperatures, which keeps sensitive materials intact.

The vacuum environment enables the drying process to be carried out at considerably lower temperatures than in traditional dryers. This aspect is essential for maintaining the physical and chemical integrity of heat-sensitive materials like drugs, food, and chemicals. By reducing the boiling point of liquids, the dryer ensures efficient moisture removal without taking a chance on thermal degradation. - Uniform Heat Distribution:

Fitted with sophisticated heating equipment, Industrial Vacuum Tray Dryers ensure even temperature distribution throughout all the trays. This uniform heat ensures that there is no risk of unequal drying, and thus every batch of material produced is up to the quality mark. The accurate control of temperature further raises the reliability of handling delicate material. - Durable Construction:

Built from high-quality stainless steel, for example, SS304 or SS316, these dryers are designed to endure. Besides sustaining the equipment for a long time, the sturdy build also guarantees maximum hygiene, which is why they find applications in pharmaceuticals, food processing, and cosmetics. Corrosion-resistant material prolongs the longevity of equipment even under harsh conditions. - Customizable Trays:

The trays used in the Industrial Vacuum Tray Dryer come in different sizes and arrangements to suit a broad spectrum of industrial processes. By making the equipment adaptable, companies can customize the equipment to suit their particular requirements, whether for small-scale laboratory use or production on a large scale. - Energy-Efficient Design:

Designed to reduce power consumption, Vacuum Tray Dryers provide superior drying efficiency coupled with cost savings in operating expenses. Energy-saving design not only supports the environment but also reduces the overall cost of ownership, making it an environmentally friendly option for industries. - cGMP Compliance:

In compliance with Current Good Manufacturing Practices (cGMP), these dryers are of very high quality and safety standards. By this compliance, the equipment is fit for applications in industries that demand utmost regulatory compliance, i.e., pharmaceuticals and healthcare.

Through these essential features, Industrial Vacuum Tray Dryers offer an ideal solution for industries that demand efficiency, reliability, and excellent drying performance.

Application Areas of Industrial Vacuum Tray Dryer

- Pharmaceutical Industry:

Industrial Vacuum tray dryers are of utmost importance in the pharmaceutical sector for drying heat-sensitive products like active pharmaceutical ingredients (APIs), intermediates, and bulk drugs. They ensure a controlled environment to preserve the chemical and physical characteristics of the products, so that efficacy and safety can be guaranteed. Moreover, they are extensively utilized for drying sterile products, injectable parts, and powders with minimal risk of contamination. - Food Processing Industry:

Industrial Vacuum tray dryers find their application in the food industry for drying delicate products such as fruits, vegetables, herbs, spices, and nutritional supplements. The vacuum condition prevents the loss of natural color, flavor, aroma, and nutrients from foods, and is hence used for manufacturing high-quality dehydrated food products. Industrial Vacuum tray dryers also find applications in the processing of food powders and ready-to-eat meal ingredients that need to be accurately dried. - Chemical Industry:

The chemical industry depends on Industrial vacuum tray dryers to dry specialty chemicals, dyes, pigments, and catalysts. These items are typically heat and air sensitive, and the vacuum drying method avoids oxidation and heat degradation. The dryers ensure that the chemical mixtures remain intact, providing uniform and predictable outcomes for commercial and industrial use. - Cosmetic Industry:

In the cosmetic industry, vacuum tray dryers are employed to treat creams, lotions, gels, and powders. The drying process helps ensure that the active ingredients are preserved and that the products' desired consistency and texture are maintained. Vacuum drying avoids contamination, which is crucial for complying with the cosmetics industry's high standards of quality. - Herbal and Ayurvedic Products:

Dehydrating herbal and ayurvedic formulations demand extra caution to maintain their medicinal properties and original essence. Vacuum tray dryers offer a low-temperature drying option that avoids bioactive compound loss, thus making them suitable for drying herbal powders, extracts, and other formulations employed in the traditional medicine market. - Research and Development Laboratories:

Industrial Vacuum tray dryers are often used in research and development laboratories for small-scale drying of experimental products. Their accuracy and capacity to cope with intricate drying requirements render them a convenient tool for testing novel formulations and processes in different industries. - Paint and Coating Industry:

Vacuum tray dryers in the coating and paint industry serve to dry pigments and powders with controlled moisture levels for maximum efficiency. The technology facilitates drying of materials evenly, which is required for developing uniform color and texture in finished products. - Electronics and Semiconductors:

Vacuum tray dryers in electronics are utilized to dry sensitive materials and components and adhesives to moisture and temperature changes. Vacuum helps to dry the materials extensively and evenly, which is vital in ensuring the reliability and operation of electronic devices.

Advantages of Industrial Vacuum Tray Dryer

- Delicate Product Preservation:

Ideal for drying sensitive materials like pharmaceuticals, chemicals, and food products without compromising their quality. - Oxidation Prevention:

The vacuum environment minimizes oxidation and contamination, preserving the integrity of the products. - Enhanced Productivity:

Reduces drying time significantly, allowing for higher production efficiency. - Cost-Effective Operations:

Minimum operator intervention lowers labour costs and improves overall cost-effectiveness. - Very easy Maintenance:

Fitted with easy-to-clean and removable trays for convenient maintenance and durability.

How to Select the Best Industrial Vacuum Tray Dryer

Choosing the right vacuum tray dryer requires careful consideration of various factors to ensure it meets your specific requirements:

- Capacity:

Determine the batch size and production volume to choose a dryer with the right number of trays and chamber size. - Material of Construction:

Opt for high-grade stainless steel (SS304/SS316) for superior hygiene, durability, and resistance to corrosion. - Heating Mechanism:

Assess whether you need electric, steam, or thermal fluid heating, depending on the application and energy efficiency requirements. - Automation Level:

Look for options like PLC-based automation, which can enhance operational efficiency and reduce manual intervention. - Compliance Standards:

Ensure the dryer adheres to cGMP and other industry standards for safety and quality. - Customization:

Choose a manufacturer who offers customization to cater to specific operational and layout needs. - After-Sales Support:

Evaluate the manufacturer's support services, including installation, training, and maintenance.

Why Choose Bipin Pharma for Industrial Vacuum Tray Dryers?

With years of experience and a focus on quality, Bipin Pharma is a reliable partner for companies seeking effective drying solutions. Our vacuum tray dryers are not just versatile but also optimized to improve productivity and deliver high-quality output for a range of applications.

Select Bipin Pharma for the latest drying technology and unparalleled customer service.

Conclusion

A vacuum tray dryer is an essential equipment for industries that handle heat-sensitive or easily degradable products. Its efficiency in providing contamination-free, efficient drying makes it a preferred choice in several industries, including pharmaceuticals, food, cosmetics, and chemicals. Depending on your production requirements and choosing the proper features, you can achieve peak performance and long-term reliability.

To learn more about high-quality Industrial vacuum tray dryers, visit the following product pages: